Physiowear

CA Design

Project Overview

In this project a pair of smart compression shorts was created to monitor user posture and provide discreet corrective feedback via haptic at the waistline above the hip bones. This was done using a combination of machine knitting, conductive textiles, bespoke hard to soft interfacing and micro-controller to process sensing inputs and provide signals to haptic actuators.

The project was a proof of concept that it was viable to build soft sensing garment using conductive yarns and 3D knit technologies to deliver a garment that could help the user manage back pain and rehabilitation discreetly at a low layer.

Multiple factors needed to be researched to deliver a working prototype of this garment. This took a multi-pronged approach with the goal of marrying together the research outputs into a functional system:

-

Anatomical research: Biomechanical, Skin and muscle stretching, Lines of Non-Extension (LoNE)

-

Engineering and design research on e-textiles, conductive yarns and 3D machine knitting processes

-

Using a microprocessor development board to combine IMU data and inputs from soft sensing elements.

-

Explored anatomical positions and corresponding stretch patterns in compression shorts relative to leg and back positions.

Develop concepts based on research into LoNE, langers lines and musculature biology.

Test the electrical performance of swatches of knitted conductive yarns and gauge impedance of conductive steel fibres and tarnished silver yarns.

Work with machine knitting machinest to develop core understanding of manufacturing technologies, capabilities and limitations.

-

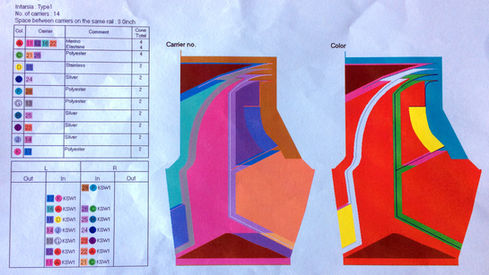

Developed garment concepts that used machine knitting to embed conductive yarns into textile panels for later manufacture.

-

Use lines of non-extension to create circuit map to minimize strain on soft circuit and deviation in signals caused by stretch and anisotropy.

-

Design embedded conductive fibres to create stretch sensors with conductive steel fibres and use tarnished silver to create circuit paths based LoNEs. Develop internal routing in waist band for haptic feedback using conductive silver.

-

Design hard to soft interfacing to create snap on snap off electrical contacts between haptic motors and microprocessors.

-

Develop basic code to read inputs from stretch panels.

-

-

Worked closely with machine knit technician to create panels that incorporated soft circuitry.

Sew together panels and finish a basic garment with fully integrated conductive yarns. -

CAD design for housing for microcontrollers, haptic actuals and bespoke hard to soft connectors.

-

3D print housings to dial fits and connections

-

-

Test integrated soft circuits to establish correct impedance values for resistor selection.

-

Test power required to drive haptic actuators.

-

Test fit of compression shorts for comfort and fabric performance.

-

-

Further develop soft circuit with knit machinists to dial in size and layout of stretch sensor across buttocks (derived leg/back positions).

-

Add in a second stretch at knee cuff for derived knee articulation.

-

Use 3D printing for rapid iterations of hard to soft connections and hardware housing.

-

Incorporate snap lock magnetic buttons as both physical and electrical connectors for simple power connections (V/g)

-

Develop bespoke 3-point hard to soft connectors that acquire stretch data from each side/leg.

-

Improve code to process stretch inputs and provide subsequent haptic feedback based on specific body/sensor positions

-

Incorporate IMU data into code model (processor sits at central back and has onboard IMU. This acts as positional baseline)

-

Create visual model using Processing to demonstrate 2D position of body wearing the garment.

-

Outcomes

In this project I handled most of the design, build and testing with the exception of the programming and the production of the knitted cloth, in which I worked closely with the skilled machine knitting technicians at Textile Design Lab .

Researched and identified opportunities in design space. Developed a functional model for mapping soft circuitry and optimizing performance by adapting circuit layouts to Lines of non Extension.

Produced CAD models for hardware an hard to soft interfacing. Programmed the slicing/g-code 3D printing.

Developed the 2D garment patterns for the compression shorts as well as assembling garment.

Programmed microprocessor myself, however had assistance incorporating IMU data with soft sensors and creating a visual model.

Setting up and completed testing protocols for garment.